FROM WOOL TO WOOL - AICHI - JAPAN

from wool to wool

Lear how scarcity brings reflection in Japan post-war era

A few months ago I visited Aichi province, the largest Wool production centre in Japan supported by a cottage industry of RECYCLED WOOL, dating back from the 50th.

“All fabric is used when cutting a Kimono but Western suits generate 20% fabric loss”. This small phrase caught my attention and my mind started to think about this Mom & Pap’s wool workshops puzzled by the accumulation of valuable rubbish generated by the new corporate and fashion demands in bloodless post-war Japan.

Knowing a bit Japan and its people, I let my mind wonder about how a recycled industry could take roots out of necessity but also culture.

“Mottai-Nai “ is a popular expression meaning “regrets over wast” and since Japan wool business started without raising its own sheep, scarcity was taken into account from the start.

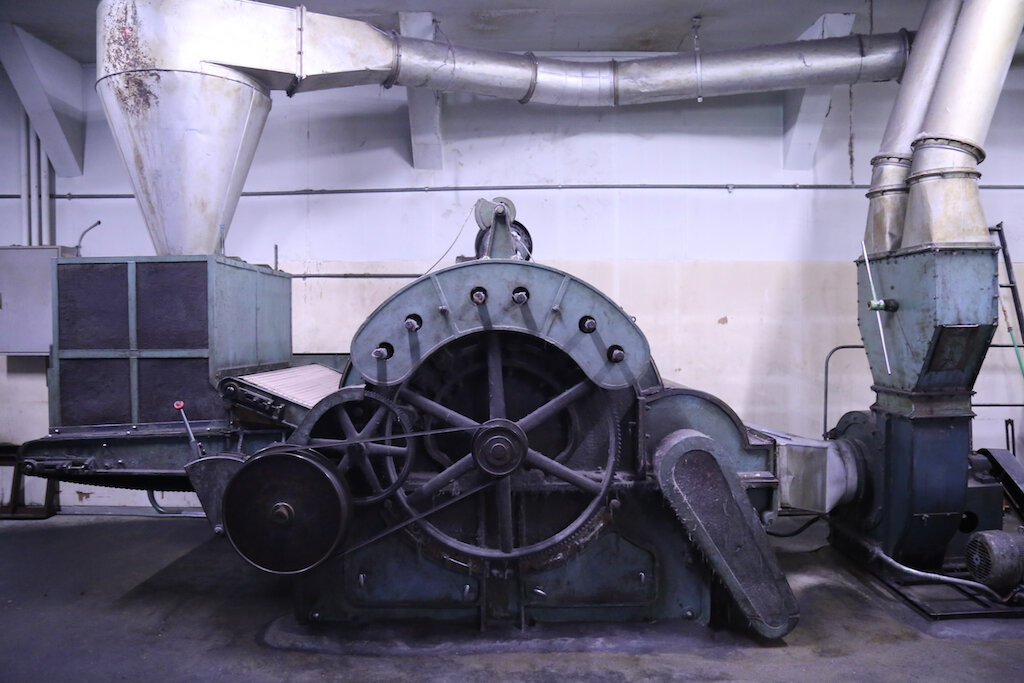

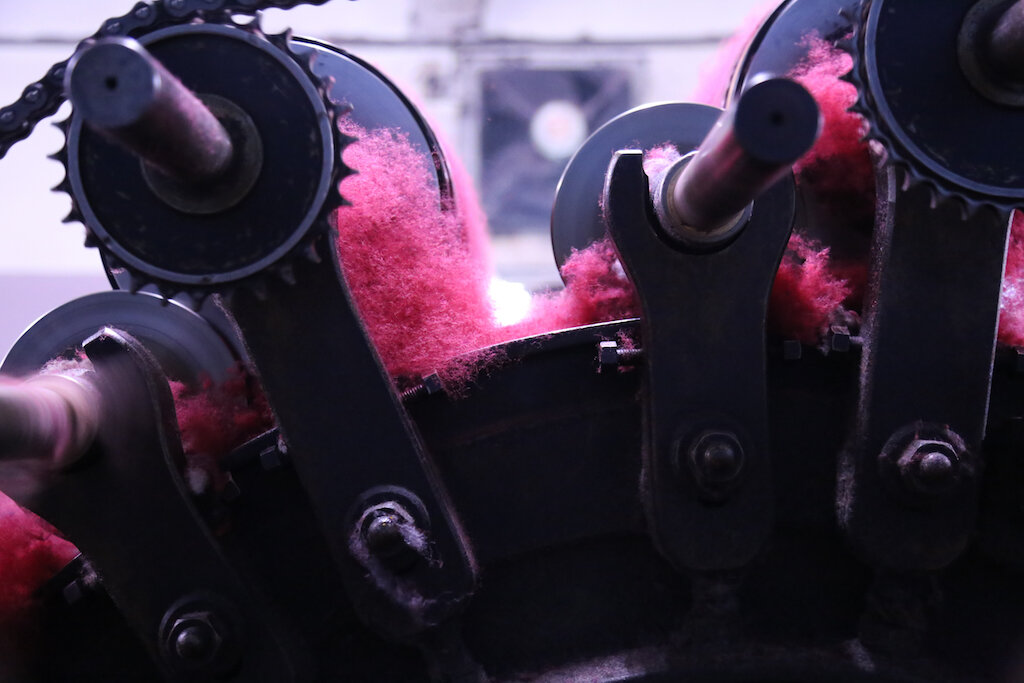

Leftovers pieces were collected from large mills, sorted, shredded, then spun into new colourful threads according to weaving mills demands.

It was a thriving economy back then. A transparent process of new and recycled thread weaved back into new fabrics. Something normal and “undisclosed” as the Mottai-nai philosophy made it more important to care for waste than the finality of things.

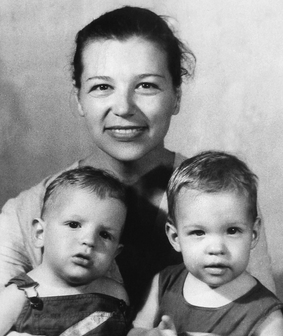

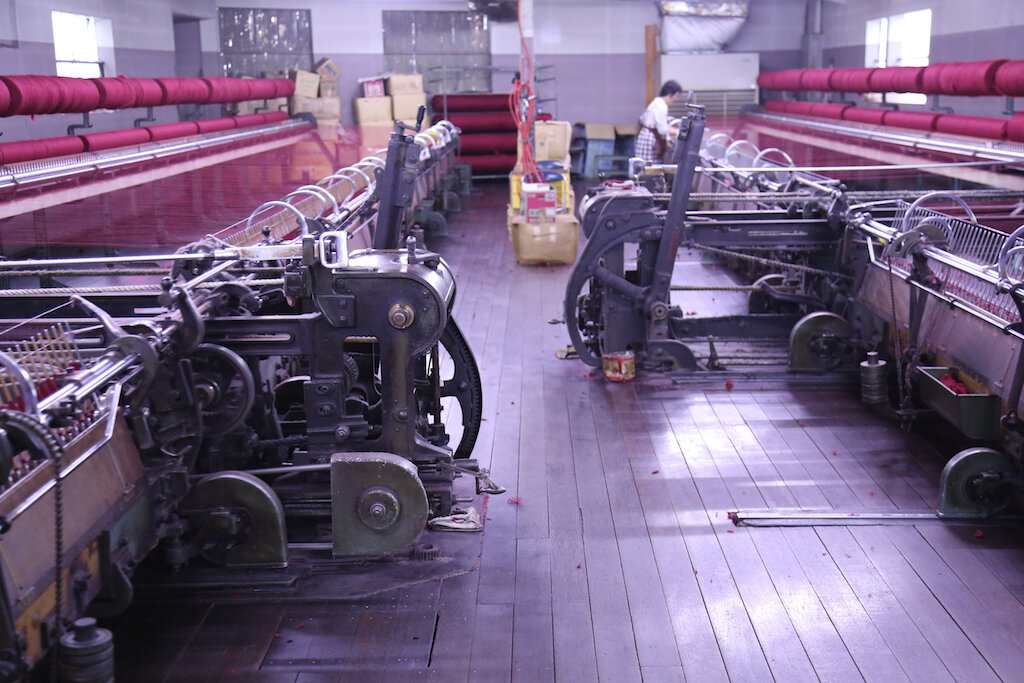

In the past, small workshops were set-up in family backyards and everyone was involved from grandparents to kids. Rarely a family could cover all the process so workshops share workloads, cooperating with each other, some collecting left-overs, other shredding, other ones spinning.

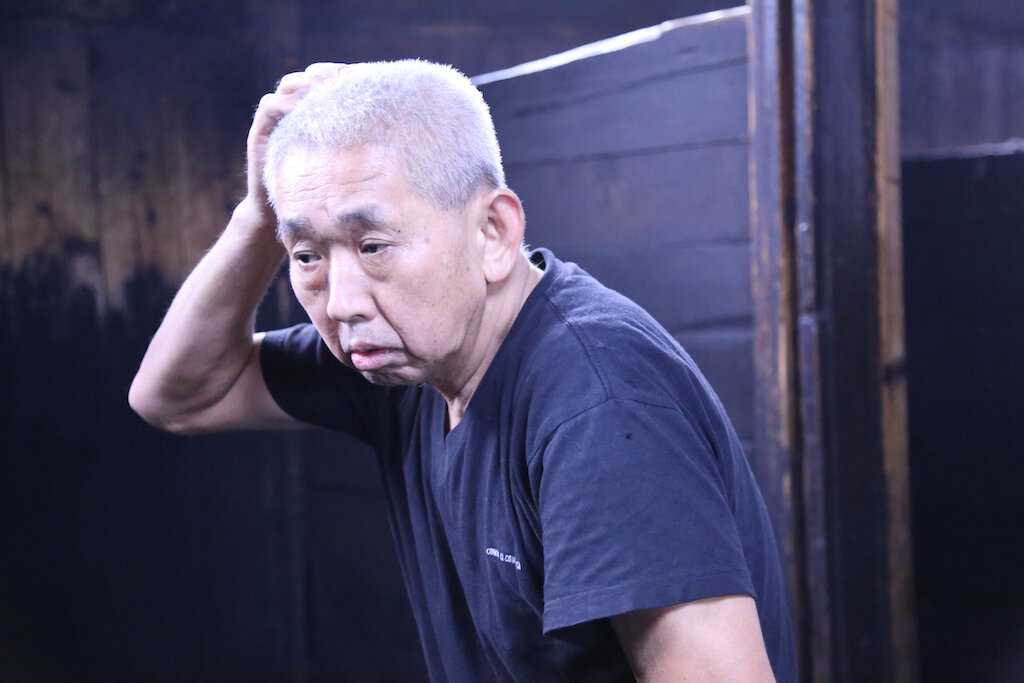

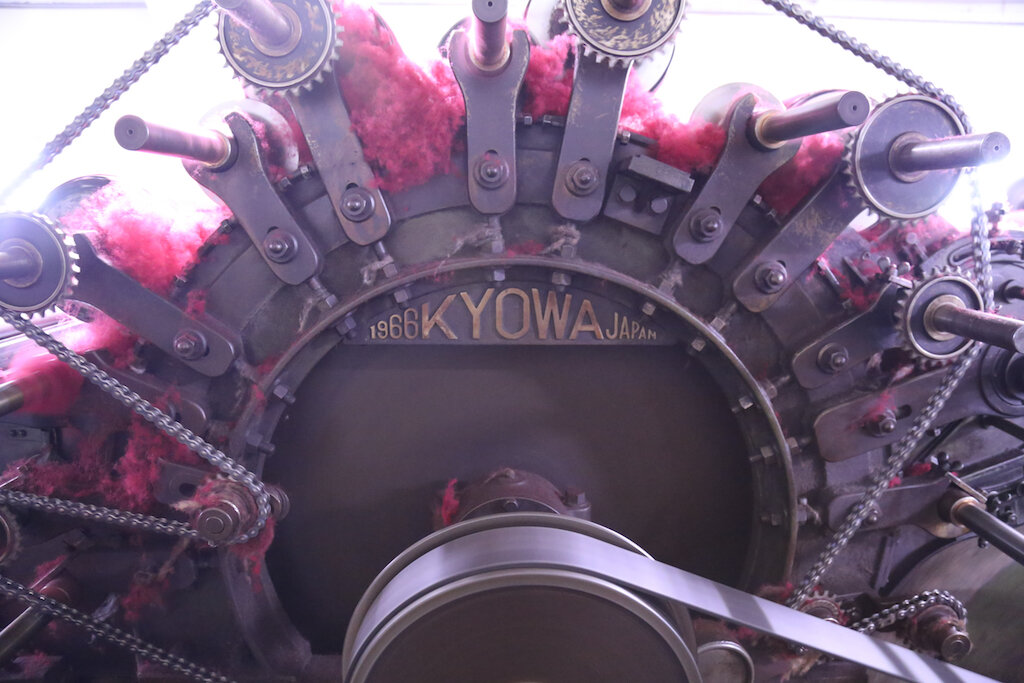

The 50’s invented new types of machinery that are still in use today. Unfortunately, too old, too dangerous, time-consuming and generating too little revenues, they look-like the people who served them, fragile, tired and on the verge of collapse.

Talking to designers from BLANKET, a Japanese brand using local recycled wool while trying to finding a way to save Aichi craft industry. We met artisans able to generate interest from Fashion brands such as MUJI or PATAGONIA but the real need is to tackle our global problem of accumulated garment wast with new technology and science -( 85% of global garment waste is not recycled at the moment).

This Japanese workshops, although wonderful and useful in their time, no longer have a place in today’s fashion needs except as museums and storytelling, gently dusting under Aichi drizzle, obsolete and not profitable. New technologies have to come to the rescue.

Developing circular recycling technologies for textiles, replacing virgin resources with recaptured raw materials - by WORN AGAIN Technology

Today’s methods for textile-to-textile recycling are extremely limited. They can neither separate out dyes and other contaminants that went into textiles, nor separate mixed fibres, such as polyester and cotton blends.

As a result, less than 1 per cent of existing textiles go back into the making of new textiles, while an estimated 53 million tonnes of textiles are going to landfill or incineration every year worldwide.

To add to these challenges, the demand for raw materials to make new textiles is set to increase by 63 per cent in the next 10 years.

Clearly, new solutions to meet future resource demands are needed.

’Worn Again Technologies’ pioneering polymer recycling technology is able to separate, decontaminate and extract polyester and cellulose (from cotton) from non-reusable textiles and polyester bottles and packaging to be made back into new products in the existing supply chains.

The aim of their technology is to enable these recaptured resources to be kept in constant circulation, driving positive economic, social and environmental benefits, competitively processing blended inputs and producing dual outputs while preserving global resources.